As much as we love learning about warehousing at American Storage and Logistics, it’s pretty safe to assume that most folks don't spend a lot of time pondering the different types of warehouse racking and industrial shelving. And for that very reason, it’s pretty common for warehouses to be designed sub-optimally. There are actually several types of racking and shelving options for any given warehouse, and by utilizing the right products in the right situations, warehouse efficiency can go way up.

Are you looking for ways to cut costs, increase storage capacity, and improve the efficiency of your warehouse? While your warehouse layout is certainly a factor, your choice in racking can also have a big impact. In this blog post, we’ll look at many different types of warehouse racking products, and where each one is the most useful.

Pallet Racking

Pallet racking is the most common type of warehouse racking, as it’s engineered to store — you guessed it — pallets. If you’re running a warehouse, it’s highly likely that pallet racks make up most of your storage. While pallet racks are perfectly acceptable for most situations, depending on them for everything can negatively affect your storage and efficiency.

The Benefits of Pallet Racking:

- Common and Easy to Use: Pallet racks are by far the most ubiquitous form of racking, so most warehouse workers and managers already have an understanding of how to use them.

- Versatile: Pallet racks are essentially just raised platforms, so they’re highly versatile. They can store a wide variety of products, though it should be noted that in certain situations, it becomes more efficient to consider specialized shelving instead.

- Highly Adjustable: Pallet racks can be arranged in a layout of your choosing and they’re modular in nature. It’s easy to configure them and rearrange them into new layouts if necessary.

- Affordable: Because pallet racks are so common, they’re one of the most affordable racking options, and they are also available in refurbished and used varieties. We encourage you as American Storage and Logistics about our refurbished pallet racks if you’re looking to save money.

Industrial Shelving

While pallet racks are undeniably useful, they can waste space when they’re not being used to their full potential, and any warehouse worker knows that there are often small items that aren’t available in large enough quantities to warrant their own rack. In this situation, you have two options — put them on a pallet rack and leave a lot of space unused, or invest in a much more economical and spacially effective option. If the latter sounds appealing, industrial shelving is the solution you’re looking for.

Industrial shelves are the bookcases of the warehousing world — they’re meant for smaller items that are meant to be easily accessible and hand-picked. Industrial shelves are a fraction of the size of pallet racks, allowing you to save valuable space in your facility.

The Benefits of Industrial Shelves

- Cheaper Than Pallet Racks: Industrial shelves are the cheapest warehouse storage option. They’re also the most limited in functionality, but that’s okay when you’re buying them specifically for their intended purpose.

- Smaller: Industrial shelves don’t go very deep because they’re meant for small boxes and individual items. You can save a lot of floor space by strategically placing these in places where pallet racks wouldn’t fit.

- Ideal for Hand-Picking: Some products are best kept in spaces where they can be grabbed quickly and easily by someone on the floor. When you’re dealing small automotive parts, nuts, bolts, and other miscellaneous items, this is a major boon. Save the big, heavy items for forklift access.

- Convertible to Mezzanine: Industrial shelves can convert into a shelf-supported mezzanine down the line if you so choose. While many warehouse owners opt for single-story shelves, it’s also possible to stack them for optimal space efficiency.

Engineered Pallet Racks

In a warehouse, you always seem to be bottlenecked by something. If the amount of product you handle starts outgrowing your warehouse space, engineered pallet racks might be a good option for you. There are two main types of specialized pallet racks, and they both aim to increase warehouse storage density. These, unfortunately, tend to lower efficiency, but sometimes the trade-off is worth it — especially when it saves you from having to invest in additional real estate.

Drive-In and Drive-Thru Pallet Racks

These pallet racks provide high-density storage, as they remove any limitations to pallet depth. You can remove aisles entirely by creating deep drive in/drive-thru racking areas. This makes products harder to access, but packed much more tightly.

The Benefits of Drive-In and Drive-Thru Racks

- Good for High Quantities of a Single SKU: When you’re packing pallets super deep, it doesn’t matter a whole lot if they’re all the same product. If you manage SKUs that have copious amounts of pallets, you’ll store them far more efficiently with this method.

- Ideal for LIFO or FIFO Setups: Drive-in racks are loadable from one side, while drive-thru racks can be loaded from front and back. The former is ideal for last-in, first-out setups, while the latter is good for first-in, first-out. LIFO is well-suited for products that can sit dormant for long periods of time, while FIFO is designed for time-sensitive items such as seasonal products and perishables.

- 75% Space Increase: Drive-in/drive-thru setups can accommodate 75% more pallets than normal racks can. Talk about a space saver!

Pushback Pallet Racks

Pushback racks are fairly similar to drive-in pallet racks. They both favor a LIFO system, and they’re good for SKUs that have 5+ pallets. The main difference is the loading mechanism, in which pallets are placed on nested carts. They get pushed to the back when they’re loaded, and they roll to the front when they’re next in line for unloading.

The Benefits of Pushback Pallet Racks:

- Can Place a Different SKU On Each Level: Unlike drive-in racks, you can place different SKUs on each level, allowing for more selectivity.

- 90% Increase in Pallet Capacity From Standard Racks: Similar to drive-in racks, this system is much more dense, allowing for a 90% increase in pallet capacity.

- Saves Space Without Compromising Selectivity: In most space-saving situations, selectivity is compromised. Not the case with pushback racks!

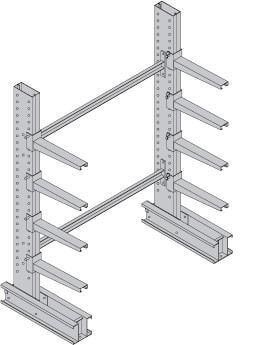

Cantilever Racks

Some types of products aren’t well-suited for pallet racks. If you’ve ever had to store large quantities of long, heavy items such as pipes, bars, and furniture, then you know that they can awkwardly stretch over multiple racks at a time, while still leaving space on the side that can’t really be occupied by anything else. Cantilever racks solve that problem — they’re explicitly designed for long products, providing the exact amount of space that’s needed without wasting room.

The Benefits of Cantilever Racks:

- Uninterrupted Storage: Cantilever racks don’t have vertical barriers, which means that you can have uninterrupted storage for long, bulky, and awkward items.

- Specialized For Certain Products: Because cantilever racks are specifically designed for certain types of products, you only need to order as many as are necessary for your situation, making warehouse layout design much easier.

- Modular: Cantilever racks are highly modular — you can make them as horizontally long as you want, stack them on top of each other, add platforms, extend the length of the arms, and so on.

Mezzanines

Mezzanine structures are pretty ambitious in scope, but extremely worth it when they’re used to their intended effect. These are essentially raised platforms that can go as high as you need — allowing you to add new floors to your warehouse. The major boon of mezzanines is that they allow you to take advantage of your unused vertical space. If you’ve got high ceilings, think of how much more you could fit up there if you just had access!

The Benefits of Mezzanine Racks

- Multi-Purpose: Mezzanines can effectively add a new floor level to your warehouse, which can be used for a variety of purposes. You can use it to store new products and conduct business as usual, use it as a storage area for tools, or even implement a second-story office.

- A Good Alternative to Expansion: Adding new space to a warehouse and/or relocating are very ambitious, costly ventures. But clever use of mezzanines can add tremendous amounts of new space.

- Maximum Floor-Level Efficiency: Some people use mezzanines as another platform for product storage, but others use them to free up floor space so that they can reserve the entire ground level for warehouse operations.

Ask Us About Warehouse Racking and Design

At American Storage and Logistics, we’re committed to helping warehouse owners all over to maximize their efficiency, save money, and free up space. We offer warehouse racking products in all of the varieties above, and we’re committed to providing them at affordable rates. Check out our online inventory!

Countless warehouses have seen enormous improvements after working with our team. Whether you’re investing in new racking products that will be game-changing for your warehouse or consulting with us on how to design the best layout, you won’t regret making the call. Ready to get started? See our website for details on our design services.